The Engineering Behind Speed: Aerodynamics Engineers

Discover the crucial role of aerodynamics engineers in motorsport. Learn how their expertise enhances performance on the track.

Table of Contents

- Introduction

- Understanding Aerodynamics in Motorsport

- The Role of Aerodynamics Engineers

- Key Responsibilities of Aerodynamics Engineers

- Tools and Technologies Used by Aerodynamics Engineers

- Challenges Faced by Aerodynamics Engineers

- The Impact of Aerodynamics Engineers on Motorsport Success

- The Future of Aerodynamics Engineering in Motorsport

- Conclusion

Introduction

In the high-stakes world of motorsport, every fraction of a second counts. Aerodynamics engineers play a vital role in this arena, using their expertise to enhance vehicle speed, performance, and safety. This article delves into the critical contributions of aerodynamics engineers, exploring how their work influences every aspect of racing. From the principles of aerodynamics to the advanced technologies they employ, we’ll uncover the essential elements that make these engineers indispensable to motorsport success.

Understanding Aerodynamics in Motorsport

What is Aerodynamics?

Aerodynamics is the study of how air interacts with solid objects—in this case, vehicles. It involves analyzing the flow of air over and around a car to understand how it affects speed, stability, and efficiency. Aerodynamics is crucial in motorsport because it directly impacts a car’s performance on the track. By managing air flow, engineers can reduce drag, increase downforce, and improve overall vehicle handling.

How Does Aerodynamics Affect Motorsport Performance?

Aerodynamics affects multiple facets of a vehicle’s performance:

- Speed and Acceleration: Reduced drag allows cars to move faster and accelerate more quickly.

- Handling and Stability: Increased downforce improves tire grip, enhancing stability during high-speed maneuvers.

- Fuel Efficiency: Optimized aerodynamics can lead to better fuel consumption, allowing cars to run longer on less fuel.

- Tire Wear: Proper aerodynamic balance can reduce excessive tire wear, extending the life of the tires and maintaining performance over longer distances.

By optimizing these factors, aerodynamics engineers help teams achieve the perfect balance between speed, efficiency, and durability.

The Role of Aerodynamics Engineers

Who Are Aerodynamics Engineers?

Aerodynamics engineers are specialized professionals with a deep understanding of fluid dynamics and vehicle design. They typically hold degrees in aerospace engineering, mechanical engineering, or a related field. Key skills include proficiency in computational fluid dynamics (CFD), experience with wind tunnel testing, and a strong foundation in physics and mathematics. These engineers work closely with other technical teams to ensure that aerodynamic improvements integrate seamlessly with the overall vehicle design.

How Do Aerodynamics Engineers Work in Motorsport?

In motorsport, aerodynamics engineers play a collaborative role, working alongside design engineers, performance analysts, and drivers. They use tools like wind tunnels and CFD software to simulate and test aerodynamic properties. Their tasks include designing aerodynamic components such as wings, diffusers, and body shapes, and validating these designs through rigorous testing. By analyzing data from both simulations and real-world tests, they continually refine and enhance the aerodynamic performance of the vehicle.

Key Responsibilities of Aerodynamics Engineers

Designing Aerodynamic Components

Aerodynamics engineers are responsible for designing components that improve the vehicle’s interaction with air. These components include:

- Front and Rear Wings: These create downforce, improving grip and stability.

- Diffusers: These manage airflow under the car, reducing drag and increasing downforce.

- Bodywork: The overall shape of the car affects how air flows around it, impacting speed and handling.

Testing and Validation

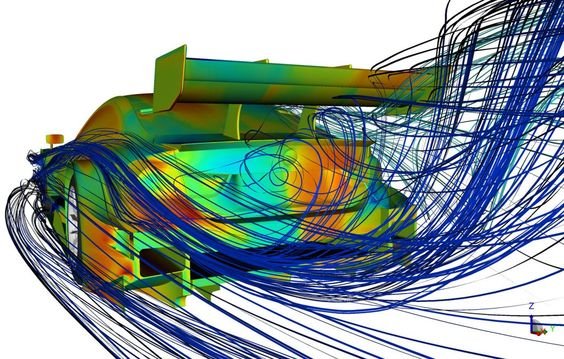

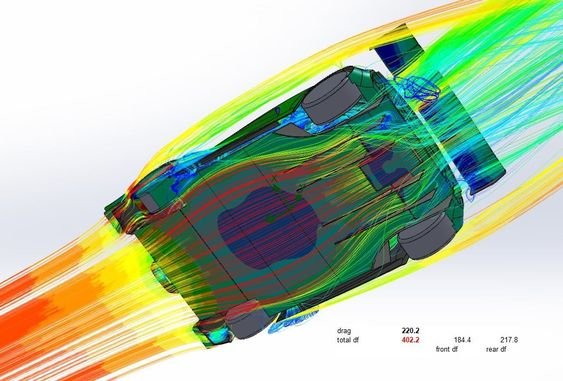

Once designed, aerodynamic components must be rigorously tested. Engineers use wind tunnels and CFD simulations to evaluate performance. Wind tunnels allow for real-time observation of airflow and pressure distribution, while CFD provides detailed simulations that can predict aerodynamic behavior under various conditions. Validation ensures that the designs perform as expected in real-world scenarios.

Continuous Improvement

Aerodynamics is a field of constant innovation. Engineers must stay updated with the latest technologies and methodologies to keep improving vehicle performance. This involves regular testing, data analysis, and iterative design adjustments. Continuous improvement is critical for maintaining competitive advantage throughout a racing season.

Tools and Technologies Used by Aerodynamics Engineers

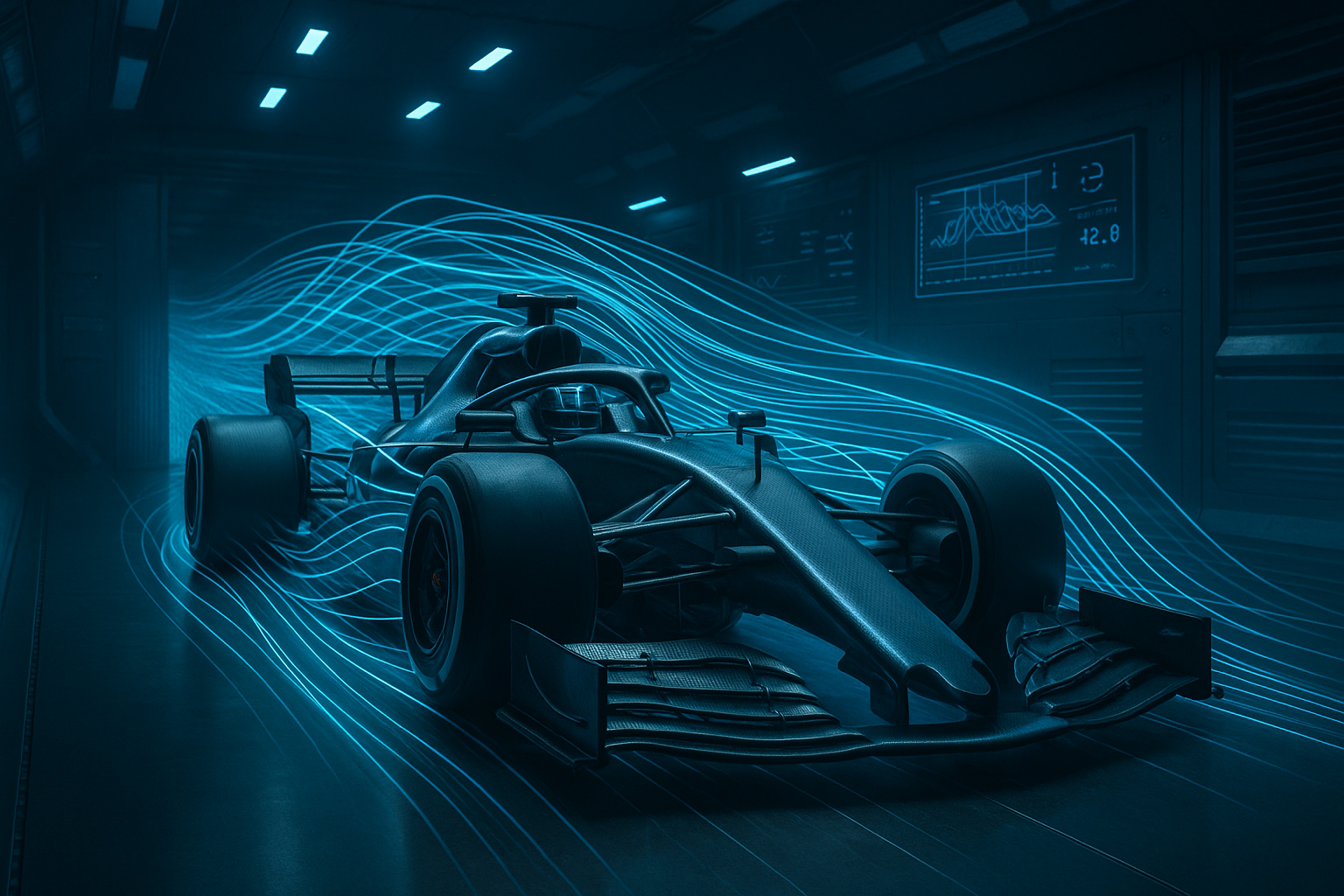

Wind Tunnels

Wind tunnels are essential tools for testing and refining aerodynamic designs. They simulate real-world air flow conditions, allowing engineers to observe and measure the effects on a scale model or full-sized vehicle. Wind tunnel testing helps identify areas of improvement and validate the effectiveness of aerodynamic components.

Computational Fluid Dynamics (CFD)

CFD is a powerful tool that uses numerical analysis to simulate fluid flow. It allows engineers to visualize and analyze how air moves around the vehicle, providing detailed insights into aerodynamic performance. CFD is cost-effective compared to physical testing and can simulate a wide range of conditions, making it indispensable in modern aerodynamics engineering.

Table: Wind Tunnel Testing vs. CFD Simulations

| Criteria | Wind Tunnel Testing | CFD Simulations |

| Cost | High | Moderate |

| Flexibility | Limited to physical changes | Highly flexible, numerous scenarios |

| Detail and Accuracy | High | High |

| Time | Longer, setup and testing time | Faster, especially for iterative tests |

Aerodynamic Simulation Software

Aerodynamic simulation software tools, such as ANSYS Fluent and OpenFOAM, are used to conduct CFD analyses. These tools help engineers model complex fluid flows and predict aerodynamic performance accurately. They provide a virtual testing environment that complements physical wind tunnel tests, enabling more comprehensive analysis and faster design iterations.

Challenges Faced by Aerodynamics Engineers

Balancing Performance and Regulations

Aerodynamics engineers must design within the constraints of motorsport regulations. These rules can limit the dimensions, shapes, and placements of aerodynamic components. Engineers must find innovative ways to maximize performance while adhering to these regulations.

Managing Trade-Offs

One of the biggest challenges is balancing downforce and drag. Increasing downforce improves grip and stability but can also increase drag, reducing top speed. Engineers must optimize these trade-offs based on track conditions and race strategies.

Adapting to Changing Conditions

Motorsport is dynamic, with conditions that can change rapidly. Weather variations, track conditions, and even competitor strategies can affect aerodynamic performance. Engineers must be able to quickly adapt and modify aerodynamic setups to maintain optimal performance.

The Future of Aerodynamics Engineering in Motorsport

Emerging Trends and Technologies

The future of aerodynamics in motorsport looks promising with the advent of new technologies like machine learning and AI-driven simulations. These technologies can process vast amounts of data to identify optimal aerodynamic solutions more quickly and accurately. Additionally, advanced materials and manufacturing techniques are opening new possibilities for innovative designs.

The Role of Sustainability

Sustainability is becoming increasingly important in motorsport. Aerodynamics engineers are exploring ways to make vehicles more energy-efficient by reducing drag and improving overall aerodynamic efficiency. This not only enhances performance but also aligns with the global push towards greener technologies.

Conclusion

Aerodynamics engineers are at the heart of modern motorsport, driving innovation and performance through their expertise in managing airflow around vehicles. Their work not only enhances speed and handling but also improves safety and fuel efficiency. From the initial design of aerodynamic components to rigorous testing and continuous improvement, these engineers ensure that racing teams stay at the forefront of technological advancements.

As we look to the future, the role of aerodynamics engineers will become even more critical. Emerging trends and technologies, coupled with a focus on sustainability, will shape the next generation of racing vehicles. For aspiring engineers and motorsport enthusiasts, understanding the importance of aerodynamics offers a pathway to contributing to one of the most exciting and dynamic fields in engineering.