Understanding the HANS Device: Revolutionizing Safety in Motorsports

Table of Contents

-

-

Introduction

-

What is the HANS Device?

-

How Does the HANS Device Work?

-

Historical Background of HANS Device

-

Regulatory Changes and Mandatory Use

-

Innovations and Improvements in Design

-

Recognitions and Awards

-

Different Models and Their Features

-

Maintenance and Care for HANS Devices

-

Community Engagement and Support

-

Conclusion

-

Key Takeaways

-

Introduction

In the high-stakes world of motorsport, where drivers routinely face lateral forces above 4g and crash impacts exceeding 50g, safety is no longer a secondary consideration — it’s engineered into every millisecond of competition.

Among the most impactful advances in motorsport safety is the HANS device, short for Head and Neck Support. Designed to prevent life-threatening injuries during high-speed crashes, the HANS system has redefined how drivers survive deceleration forces that once proved fatal.

Why Does It Matter?

Imagine this: your car hits a wall at 200 km/h. In a fraction of a second, your body stops — restrained by a harness — but your head wants to keep going. This violent whip effect places immense strain on your cervical spine, especially at the atlanto-occipital joint, where the skull connects to the vertebrae.

The result? Often, it’s a basilar skull fracture — a catastrophic injury that has claimed the lives of legends.

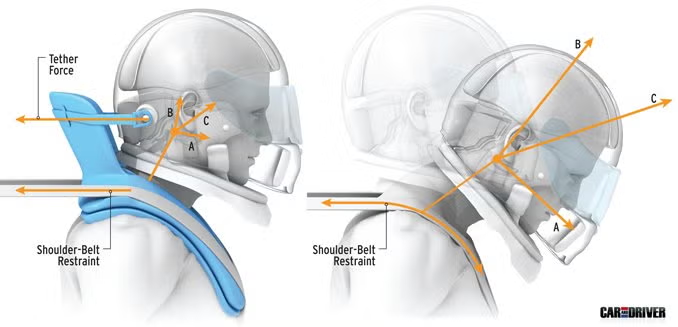

The HANS device addresses this problem through a deceptively simple concept: redirecting force. Using a rigid yoke worn over the shoulders, connected by tethers to the helmet, it channels the kinetic energy of a crash away from the neck and into the stronger structures of the shoulders and chest.

But don’t let the simplicity fool you. This is a product of biomechanical engineering, material science, and decades of motorsport evolution.

What You’ll Learn in This Guide

In this post, we’ll explore:

-

-

How the HANS device actually works (beyond marketing slogans)

-

The science behind its life-saving mechanism

-

Its origin story, from skepticism to global regulation

-

The latest innovations in materials, comfort, and usability

-

Tips on selecting the right model — and maintaining it properly

-

Whether you’re a racing driver, engineer, or enthusiast obsessed with the intersection of performance and safety, this guide offers a comprehensive, practical, and technical deep dive into the most important piece of safety equipment in modern motorsport.

Let’s get started by answering the foundational question: What exactly is the HANS device — and why is it considered the gold standard in motorsport head and neck protection?

What is the HANS Device?

The HANS device, short for Head and Neck Support, is a passive safety system designed to protect racing drivers from one of the most lethal injury mechanisms in motorsport: basilar skull fractures.

This type of injury occurs when the head, under violent deceleration, continues its motion forward while the body is restrained by the harness — creating excessive tensile forces on the upper cervical vertebrae and skull base. The HANS device was engineered specifically to interrupt this chain of events.

Engineering Behind the Design

At first glance, the HANS may appear simple — a rigid U-shaped frame resting on the driver’s shoulders. But its function is the result of decades of biomechanical research and material optimization.

Core components:

-

-

U-shaped collar: Typically made from carbon fiber reinforced polymer (CFRP), combining extreme rigidity with minimal weight.

-

Shoulder platforms: Designed to sit snugly under the harness straps, these surfaces distribute crash loads into the clavicles and sternum — structurally stronger than the neck.

-

Tether system: High-strength tethers connect the device to specific helmet anchors, limiting the forward excursion of the head during a crash.

-

How It Integrates with Driver Equipment

The HANS device is worn over the driver’s shoulders and secured in place by the existing five- or six-point safety harness. The tethers attach to quick-release anchors on each side of the helmet, ensuring:

-

-

Full freedom of motion for head rotation and visibility during normal driving

-

Force restriction only during sudden longitudinal or oblique decelerations

-

This selective restraint strategy is what makes the HANS non-intrusive in driving performance yet life-saving in high-impact events.

Material Properties Matter

Most HANS devices are constructed from aerospace-grade carbon fiber composites, offering:

-

-

High tensile and compressive strength

-

Resistance to temperature and fire

-

Minimal weight (often under 700g), preserving driver comfort

-

Some entry-level models use polymer-reinforced materials or hybrid composites, offering affordability with slightly increased weight and reduced stiffness.

What Makes It So Effective?

-

-

Prevents overextension of the neck in frontal and angular impacts

-

Distributes crash loads to stronger skeletal regions

-

Reduces neck tension loads by up to 80% in FIA crash testing

-

Integrates seamlessly into modern racing safety systems

-

In summary, the HANS device isn’t just an accessory — it’s a load path redirector that transforms the physics of a crash in favor of survivability. It’s lightweight, biomechanically efficient, and now mandatory in virtually all professional motorsport categories.

Up next: let’s understand how this system actually works during an impact.

How Does the HANS Device Work?

The HANS device functions as a biomechanical load redistribution system, designed to prevent extreme neck loading by controlling the movement of the driver’s head during a crash. Rather than absorbing energy like a crumple zone, it redirects the force pathways to more structurally resilient areas of the body — notably the clavicles and sternum.

Let’s break it down:

Step-by-Step: The Physics of a Crash

1. Inertia in Action

In a high-speed frontal or oblique impact, the driver’s body is restrained by the harness, causing an almost instant deceleration. However, the head continues moving forward due to inertia — creating dangerous stress on the cervical spine.

2. Tension on the Neck

Without the HANS device, the only things resisting this head movement are:

-

-

The neck muscles and ligaments (which are not designed for high-tension loads)

-

The base of the skull, where critical neural and vascular pathways are located

-

This is precisely what leads to basilar skull fractures and internal decapitation injuries.

3. Force Redirection with the HANS

When the HANS device is in place:

-

-

The helmet tethers engage as the head begins to move forward

-

The tethers transmit the force down through the HANS yoke, which is supported by the shoulders

-

The shoulders, in turn, are firmly secured by the racing harness

-

This creates a controlled load path, distributing energy across the thoracic cage instead of the neck — a region structurally equipped to withstand much higher forces.

What Do the Numbers Say?

-

-

In FIA and SFI crash testing, the HANS device has shown to:

-

Reduce neck tension (Fz axis) by up to 80%

-

Reduce neck extension and flexion moments by more than 60%

-

Keep head acceleration below critical injury thresholds (~80 g peak)

-

-

These reductions are not just theoretical — they correlate directly with the decline in fatal head/neck injuries since its adoption in top-tier motorsport.

Why It Works So Well

-

-

Selective constraint: Allows full range of motion during driving, engages only during high-G events

-

Load transfer efficiency: Harness + HANS + tethers create a stable load triangle

-

Stiffness matching: Materials used in the HANS frame are tuned to transmit force without deformation

-

It’s not about stopping the head — it’s about controlling how, where, and when the forces act on it.

The brilliance of the HANS device lies in this mechanical simplicity married with biomechanical precision. It doesn’t interfere until you need it — and when you do, it’s already doing its job.

Next, we’ll explore how this revolutionary idea came to life, starting with a tragic origin story that reshaped motorsport forever.

Historical Background of the HANS Device

The development of the HANS device is rooted in both engineering insight and tragic necessity. Its story begins not with a racing team or a governing body, but with two individuals who decided that fatal neck injuries should no longer be an accepted part of motorsport.

The Birth of an Idea: Dr. Robert Hubbard & Jim Downing

In the early 1980s, Dr. Robert Hubbard, a professor of biomechanical engineering at Michigan State University, began analyzing injury data from racing accidents. Around the same time, his brother-in-law, Jim Downing, a professional IMSA driver, expressed concern over the frequency of fatal crashes caused by basilar skull fractures — injuries that standard seat belts, helmets, and roll cages could not prevent.

One particular incident — the death of a mutual friend in a violent racing crash — catalyzed the pair to seek a solution.

Dr. Hubbard applied principles of injury biomechanics and crash force modeling to create a prototype that would:

-

-

Restrain the head without restricting normal motion

-

Redirect inertial loads away from the neck during an impact

-

Integrate seamlessly with existing safety gear

-

The result was the first iteration of the Head and Neck Support device — a U-shaped collar with tethers connecting to the driver’s helmet, distributing force into the shoulders.

Resistance and Reluctance: The Initial Pushback

Despite promising crash test results in controlled environments, the HANS device initially faced resistance from teams and drivers. Common objections included:

-

-

Perceived discomfort and restriction of movement

-

Weight and bulk compared to traditional gear

-

A general reluctance to adopt unproven safety innovations, especially in an era that still romanticized the dangers of motorsport

-

For nearly two decades, the HANS remained an optional and niche device, used mostly in sports car racing and by safety-conscious outliers.

The Turning Point: Dale Earnhardt’s Fatal Crash

Everything changed on February 18, 2001.

During the final lap of the Daytona 500, NASCAR legend Dale Earnhardt crashed into the wall at high speed. Although the impact didn’t appear catastrophic at first glance, the autopsy revealed a fatal basilar skull fracture — the same injury the HANS was designed to prevent.

The motorsport world was shaken. Within weeks:

-

-

NASCAR mandated the use of head and neck restraint systems

-

Formula One, CART, and other global series followed suit

-

Demand for HANS devices surged, and technical refinements accelerated

-

It took tragedy to overcome resistance — but the results were immediate: head and neck fatalities in top-level racing dropped to near zero in the years that followed.

From Prototype to Global Standard

What began as a personal engineering project became the gold standard of racing safety worldwide. By 2003, the FIA made the HANS device mandatory for all Formula One drivers, and today it is required equipment in virtually every professional racing discipline, including:

-

-

NASCAR

-

IndyCar

-

WEC

-

WRC

-

DTM

-

GT3 and grassroots racing leagues

-

The historical journey of the HANS device is a powerful example of how engineering innovation, empirical science, and personal conviction can reshape an entire industry. It’s not just a story of technology — it’s a story of lives saved, and a legacy of safety that continues to evolve.

Regulatory Changes and Mandatory Use

The journey of the HANS device, from optional accessory to mandatory safety standard, marks one of the most important cultural and technical shifts in the history of motorsport regulation.

Following a series of high-profile fatalities linked to basilar skull fractures — most notably Dale Earnhardt’s crash in 2001 — motorsport’s governing bodies could no longer ignore the overwhelming data in favor of head and neck restraint systems.

The Decision Framework: Why It Became Mandatory

Governing bodies like NASCAR, the FIA, and SFI Foundation initiated comprehensive biomechanical analyses to determine:

-

-

Injury mechanisms in frontal and angular impacts

-

The effectiveness of restraint systems in mitigating cervical spine loading

-

Integration potential with existing seat belts, helmets, and chassis designs

-

The HANS device consistently outperformed all alternatives in reducing:

-

-

Neck tension forces

-

Neck flexion and extension moments

-

Head delta-v (change in velocity) during impact

-

In most simulations, the absence of a head restraint system would result in injury thresholds being exceeded — often fatally.

Timeline of Regulation

| Year | Regulatory Milestone |

|---|---|

| 2001 | NASCAR mandates HANS or equivalent for all Cup Series drivers after Earnhardt’s crash. |

| 2002 | CART and IRL (now IndyCar) follow suit with HANS requirements. |

| 2003 | FIA mandates HANS device use in Formula One and all FIA-sanctioned categories. |

| 2004–2006 | Expansion to national and regional racing series worldwide. |

| 2010+ | Grassroots, rally, drag racing, and even niche disciplines like monster truck events begin mandating use. |

Global Standardization and Certification

Today, HANS devices are certified under:

-

-

FIA 8858-2010 or newer

-

SFI 38.1 (primarily in North America)

-

These certifications guarantee:

-

-

Structural integrity under specified g-loads

-

Compatibility with approved helmets and harnesses

-

Flame resistance and durability under extreme temperatures

-

Any device lacking certification is considered non-compliant for official competition.

A Paradigm Shift in Motorsport Safety

The regulatory mandate for HANS was more than a rule — it represented a philosophical shift in motorsport:

From accepting risk as part of the sport, to engineering risk out of the sport.

It prompted manufacturers, teams, and organizers to rethink:

-

-

Cockpit design and seat integration

-

Harness geometry to ensure proper HANS function

-

Emergency extraction procedures now adapted for HANS users

-

Today, the HANS device is non-negotiable — as essential as the helmet or fireproof suit. Its universal adoption across all levels of competition, from Formula 1 to amateur rallycross, reflects an industry now united in data-driven safety enforcement.

Innovations and Improvements in Design

Since its creation in the 1980s, the HANS device has undergone multiple evolutionary cycles — not in its fundamental function, but in its comfort, integration, and adaptability. These refinements, impulsionados por feedback de pilotos e equipes técnicas, têm tornado o dispositivo mais eficiente sem comprometer seu desempenho estrutural.

Key Engineering Improvements

1. Quick-Release Mechanisms

One of the most critical updates in modern HANS devices is the inclusion of quick-release tethers and anchor systems, allowing for:

-

-

Faster extrication in the event of a crash

-

Integration with FIA-approved emergency helmet removal protocols

-

Reduced time for rescue crews in high-risk scenarios like fire or unconsciousness

-

These systems typically use push-button or cam-lock mechanisms, and are required to meet decoupling time standards set by regulatory bodies.

2. Adjustable Tether Length and Angle

Early versions had fixed tether lengths, limiting helmet compatibility and driver comfort. Today’s models offer:

-

-

Adjustable tether lengths to fine-tune range of head movement

-

Angle-specific mounts to match different seat recline geometries (e.g., GT vs. single-seater)

-

Improved tether routing to prevent friction wear or helmet lift

-

This adjustability is crucial to optimize comfort without compromising the head movement restriction under crash conditions.

3. Ergonomic Contouring & Padding

Modern HANS devices are shaped to conform more closely to the human trapezius and shoulder profile, reducing pressure points and improving long-duration comfort — especially in endurance racing.

-

-

Use of dual-density foams for padding

-

Optional fire-retardant comfort sleeves

-

Compatibility with custom-molded seats and harness systems

-

Material Science: Strength Without Mass

Carbon Fiber Evolution

Premium HANS models now use aerospace-grade prepreg carbon fiber, offering:

-

-

High specific stiffness and tensile strength

-

Resistance to thermal degradation

-

Total weights often under 700g, minimizing driver fatigue and improving balance

-

Alternative Composites

For cost-sensitive applications, manufacturers introduced:

-

-

Injection-molded polymer composites (e.g., polyamide + glass fiber)

-

Hybrid carbon-aramid blends for mid-tier performance

-

These maintain certification standards while offering more accessible price points for semi-professional and amateur drivers.

Seamless Integration with Modern Equipment

-

-

Helmet anchor standards (FIA 8858-2010, 8858-2018) are now universal, ensuring plug-and-play compatibility with all modern helmets.

-

HANS designs also consider seat belt geometry, maintaining correct strap load paths during impact — essential for distributing forces into the yoke.

-

The Result: High-Tech, Human-Centered Safety

Modern HANS devices are now:

-

-

More compact and aerodynamic (especially for open-wheel use)

-

Customizable by discipline — from rally to GT endurance

-

More accepted by drivers, thanks to reduced physical burden and improved feel

-

These improvements have turned the HANS device from a regulatory imposition into a trusted performance tool embraced by the world’s top drivers.

Recognitions and Awards

The impact of the HANS device on motorsport safety has been so profound that it has transcended racing itself — earning accolades from technical societies, governing bodies, and academic institutions around the world.

Widely acknowledged as one of the most significant safety innovations in motorsports history, the HANS device is now recognized as a benchmark in crash injury mitigation — comparable in influence to the introduction of seat belts and crash helmets.

Key Awards and Honors

2016 – Motorsports Hall of Fame Recognition

Dr. Robert Hubbard and Jim Downing were honored for their pioneering work in developing the HANS device, which had — by that time — already saved hundreds of lives globally. The recognition highlighted:

-

-

Their engineering innovation

-

The device’s widespread adoption across all major racing series

-

The influence of their work in shaping modern motorsport safety culture

-

FIA Institute Award for Safety Innovation

The FIA Institute has acknowledged the HANS device as a cornerstone of its global safety program. It is consistently referenced in:

-

-

Technical guidelines for cockpit safety

-

FIA’s Global Safety Development Program materials

-

Research and development protocols for junior and feeder series

-

Society of Automotive Engineers (SAE) & Biomechanics Communities

Hubbard’s research has been cited extensively in peer-reviewed publications on head and neck injury metrics (e.g., HIC, Nij criteria). His work influenced:

-

-

The creation of standardized dummy neck models (Hybrid III)

-

Updates to FMVSS and FIA impact testing protocols

-

A Global Legacy of Lives Saved

Since becoming mandatory in top-tier racing series:

-

-

The incidence of fatal basilar skull fractures has dropped to near-zero

-

Over 275+ documented survivals are directly attributed to HANS usage in high-G frontal crashes

-

It has become standard curriculum in racing driver training programs and motorsport engineering courses worldwide

-

“The HANS device didn’t just save lives — it changed the trajectory of safety engineering in motorsport.”

— FIA Institute for Safety and Sustainability

Cultural Impact Beyond Motorsports

-

-

Featured in documentaries like “Rapid Response” and “Blink of an Eye”

-

Studied in automotive design universities and military crash safety programs

-

Inspired similar technologies in aviation ejection seat safety and jet fighter head restraints

-

The HANS device is more than a safety product — it is a symbol of what happens when biomechanical engineering meets human tragedy and refuses to let it repeat. Its legacy is cemented not only in awards, but in every driver who walks away from an impact that would have once been fatal.

Different Models and Their Features

While all certified HANS devices follow the same fundamental principle — redirecting crash forces away from the cervical spine — they come in various models optimized for different types of racing, driver profiles, and budgets.

A well-chosen HANS model can enhance not only safety, but also comfort, driver performance, and equipment integration.

Key Models and Their Use Cases

Below is a comparison of the most popular models currently on the market, categorized by their structural design, material composition, and ideal usage:

| Model | Key Features | Weight | Certifications | Best For |

|---|---|---|---|---|

| HANS III | Lightweight injection-molded composite. Excellent strength-to-cost ratio. | Moderate | FIA 8858, SFI 38.1 | Club racing, semi-professional motorsports |

| Z-Tech 8A | Ultra-lightweight, flexible tethers, premium foam padding. | Very light | FIA 8858, SFI 38.1 | Formula cars, sprint races, high-mobility needs |

| Z-Tech 6A | Balanced weight, comfort for long durations. Slightly more robust than 8A. | Mod-Light | FIA 8858, SFI 38.1 | Endurance racing, GT cars, rally |

| Z-Tech 2A | Entry-level poly-composite shell. Simplified tether design. | Low | SFI 38.1 | Short track, karting, grassroots motorsports |

What to Consider When Choosing Your HANS

Material Construction

-

-

HANS III uses a lightweight composite injection-molded structure — strong and cost-effective.

-

Z-Tech 8A incorporates carbon composite and kevlar layers, offering greater durability and weight savings.

-

Z-Tech 2A focuses on affordability using polymer-reinforced plastics.

-

Ergonomics & Fit

-

-

Higher-end models (like the 8A) include contoured padding, ventilation slots, and custom tether adjustability.

-

Models like the 2A offer a universal fit, though may lack the comfort required for multi-hour stints.

-

Application-Specific Features

-

-

Z-Tech 6A is designed with endurance racing in mind: longer seat time, hydration compatibility, and fatigue management.

-

Z-Tech 8A is favored by open-wheel drivers due to its minimal profile and unrestricted lateral vision.

-

Certification Overview

-

-

FIA 8858: Required for international-level circuit racing and Formula categories.

-

SFI 38.1: Accepted in most North American series; standard for NASCAR, drag racing, and grassroots events.

-

Always ensure your HANS device is current with certification standards, especially if competing in sanctioned series — expired certifications can disqualify a car from competition.

Summary Table

| Model | Weight Class | Use Case | Compliance |

|---|---|---|---|

| HANS III | Moderate | General motorsports, cost-effective option | FIA, SFI 38.1 |

| Z-Tech 8A | Ultra-light | High-performance, open-wheel use | FIA, SFI 38.1 |

| Z-Tech 6A | Mod-light | Endurance racing, GT/rally use | FIA, SFI 38.1 |

| Z-Tech 2A | Low | Entry-level, local racing | SFI 38.1 (not FIA-rated) |

Tip: When in doubt, choose based on your driving environment — duration, seat inclination, and helmet type all influence the optimal HANS configuration.

Maintenance and Care for HANS Devices

Although the HANS device is engineered to withstand extreme loads and high-energy impacts, its performance depends on rigorous maintenance and inspection routines. Like any safety-critical equipment, its longevity and effectiveness are directly tied to how well it is cared for — especially after heavy use or accidents.

1. Structural Inspection (Before and After Each Event)

After every session — especially following a crash, off-track excursion, or hard braking incident — perform a detailed check for:

-

-

Cracks or delamination in the composite shell

-

Fretting, cuts, or wear on the helmet tethers

-

Damage or distortion on the anchor mounts or quick-release points

-

Compression wear on the shoulder contact zones

-

⚠️ Any visible structural damage requires immediate replacement. Even hairline cracks can compromise load transfer performance under G-loads.

2. Cleaning Procedure

Regular cleaning ensures hygiene and material preservation without compromising surface properties.

Recommended:

-

-

Use a soft cloth, warm water, and mild, non-abrasive soap

-

Allow to air dry completely before storage

-

Remove any padding or sleeves (if applicable) and wash separately

-

Avoid:

-

-

Harsh solvents (acetone, bleach, alcohol)

-

High-pressure sprays or submersion

-

Machine washing foam or strap components

-

3. Storage Best Practices

Proper storage is essential for preventing UV degradation, thermal cycling, and moisture absorption — all of which can degrade the materials over time.

Store the HANS device:

-

-

In a ventilated, dry area, ideally inside a protective case

-

Away from direct sunlight and temperature extremes

-

Positioned flat, not under load or pressure (don’t hang it by the tethers)

-

4. Replacement Criteria

Even if unused in an accident, HANS devices should follow age-based replacement cycles, in line with regulatory recommendations:

| Component | Replacement Interval | Notes |

|---|---|---|

| HANS Shell (CFRP) | ~5 years (if undamaged) | Inspect annually; retire if crashed |

| Helmet Tethers | Every 2–3 years | Subject to fraying, UV exposure |

| Quick-release anchors | Every 2 years or as per helmet spec | Should match helmet certification timeline |

Devices involved in crashes must be inspected or replaced, even if no damage is visible.

🔧 5. Certification Validity

FIA and SFI both require valid certification labels on the HANS device and helmet tethers. These must be:

-

-

Legible and up to date

-

Unmodified or unremoved

-

Consistent with the current regulations of your racing series

-

Failure to meet certification criteria can result in technical disqualification during pre-race scrutineering.

Maintaining your HANS device is not just about prolonging its lifespan — it’s about guaranteeing its performance when it matters most. Regular care ensures the system remains fully functional, compliant, and ready to perform under the highest demands of motorsport.

Community Engagement and Support

Beyond its engineering brilliance and regulatory impact, the HANS device has become a symbol of something maior: a global, safety-focused racing culture.

As the device became standard across professional and grassroots motorsport, it also catalyzed a growing movement — one where drivers, engineers, coaches, and fans contribute at todos os níveis para promover educação, inovação e responsabilidade coletiva.

A Global Network for Safety Knowledge

Online Forums and Technical Groups

Communities such as racing subreddits, sim racing forums, and Facebook groups have become powerful hubs for:

-

-

Maintenance and fitting tips

-

Model comparisons and real-world reviews

-

Discussions on safety regulation updates

-

Sharing crash survival stories where the HANS was decisive

-

These platforms allow rookie drivers to learn from veterans, and vice versa, creating a feedback loop that supports continuous improvement.

Knowledge Sharing = Injury Reduction

Studies show that when drivers are exposed to peer-driven safety content, they’re significantly more likely to:

-

-

Inspect and maintain their safety gear regularly

-

Choose certified equipment over uncertified alternatives

-

Understand the biomechanical why behind what they’re using

-

This shift in mindset — from “what do I need to pass inspection” to “what will actually protect me” — is a cultural change, and the HANS device is at its center.

Customization, Adaptation, and Engineering Feedback

Many community members — especially those in sim racing, rally, or club-level circuit events — contribute by:

-

-

Posting custom modifications for better fit or helmet integration

-

Recommending seat and harness configurations that optimize comfort

-

Sharing CAD-based add-ons for transport, storage, or visual inspection aids

-

This grassroots engagement directly influences how manufacturers iterate their designs — often incorporating user feedback in future product lines.

Building a Culture of Accountability

“Racing is dangerous, but it doesn’t have to be deadly.”

— Common mantra in driver development programs

Teams, driving schools, and even sim racing leagues now include HANS orientation as part of their training — not just for compliance, but to instill a deeper understanding of its function.

Workshops and online courses often include:

-

-

How to fit a HANS correctly

-

How to choose between FIA/SFI models

-

When to replace equipment (beyond regulations)

-

Real Impact, Real Stories

Many drivers attribute their survival to the HANS device — and they share these stories online, amplifying the importance of using the equipment properly. From F1 to local kart clubs, the device has become more than a piece of gear — it’s a statement of respect for the sport, the machine, and life itself.

In short, the HANS device is not just a product — it’s a community touchpoint, a conversation starter, and a catalyst for cultural transformation within motorsport. And it’s through these global networks of engagement and shared knowledge that the true value of the device continues to grow.

Conclusion

The HANS device stands as one of motorsport’s greatest safety achievements — not merely a product of engineering, but the result of decades de inovação, pesquisa biomecânica e tragédias que não podiam mais ser ignoradas.

From its initial resistance to universal adoption, the HANS device has transformed the philosophy of racing safety. No longer is survival in a crash a matter of luck; it is a matter of science, preparation, and responsibility.

By understanding its function, development, and real-world effectiveness, we equip ourselves — as drivers, engineers, enthusiasts, or fans — with the knowledge needed to value and demand safety at every level of the sport.

More than a device, the HANS is a statement: that performance and protection can, and must, coexist. And in every race where a driver walks away from what would’ve once been a fatal impact, this innovation proves its worth again.

Key Takeaways

-

-

Biomechanical Protection: The HANS device redirects head movement forces into the shoulders, drastically reducing the risk of basilar skull fractures.

-

Regulatory Standard: Mandatory across Formula 1, NASCAR, IndyCar, WEC, and virtually all professional and grassroots racing series.

-

Design Evolution: Ongoing improvements in ergonomics, materials, and quick-release systems make it lighter, more comfortable, and user-friendly.

-

Maintenance is Critical: Regular inspection, cleaning, and tether replacement are essential to preserve performance and comply with certifications.

-

A Culture Shift: The HANS device represents more than safety — it embodies a movement to prioritize the lives of drivers over tradition and resistance.

-

If you race, you need HANS. If you watch racing, you should understand why it matters.

If this guide helped expand your understanding of motorsport safety, consider sharing it with your racing community. Let’s continue to push the culture of performance forward — with safety as the foundation.